What Is Asset Performance Management?

Assets are the physical plant, equipment and supporting infrastructure that supports the operation of a business. For example, the topside equipment of an Oil & Gas platform, the turbine and blades of an offshore wind farm or the rented power generators on a construction site. Asset Performance Management (APM) is a strategy that uses a suite of software applications to optimise the reliability and availability of assets essential to an enterprise‘s operation. APM software will predict imminent failure, identify and alert fault modes, reduce unplanned repair work and increase asset availability.

APM solutions are now extending beyond maintenance to automate operational processes that interact with the asset. For example, auto-monitor equipment moving through the supply chain and warn of potential delays.

Historically, APM has been implemented only by large companies with the necessary internal resources to manage the complex implementation and integration challenges. The first generation of APM solutions are therefore costly, often require on-premise implementations with up-front licence fees and do not embed modern Artificial Intelligence (AI) techniques to improve predictability and usability.

Now, the latest generation of APM solutions has made it possible for businesses of any size to implement APM across their asset base rapidly.

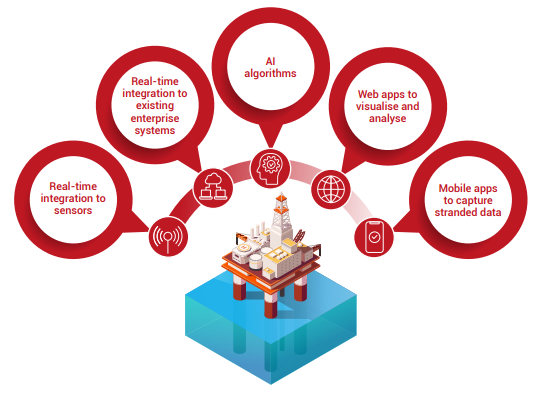

Modern APM solutions have five core components

Real-time integration to sensors and other operation data (e.g. Operator Rounds Readings) relevant to each item of plant and equipment under surveillance.

Real-time integration to existing digital infrastructure. For example, Enterprise Asset Management (EAM) systems, Computerised Maintenance Management Systems (CMMS), Data Historians, Telematics, SCADA, Enterprise Resource Planning (ERP) and Production Loss Management Systems (PLMS).

Artificial Intelligence (AI) algorithms that continually monitor the status of a real-time digital twin of each instance of plant and equipment.

Web apps to visualise and analyse the historical, current and predicted state of plant and equipment.

Mobile apps to capture stranded data (i.e. data manually captured) and execute maintenance and inspection fieldwork.

This blog is an excerpt from our “Guide to Asset Performance Management for Oil & Gas Operators“. Download the full guide for more insights, such as “Why are Physical Assets Underperforming?“.